Hi-Q PLAS CO., LTD.

PLASTIC INJECTION MOLDING THAILAND

Specializing in precision automotive and electrical plastic components.

WELCOME TO HI-Q PLAS

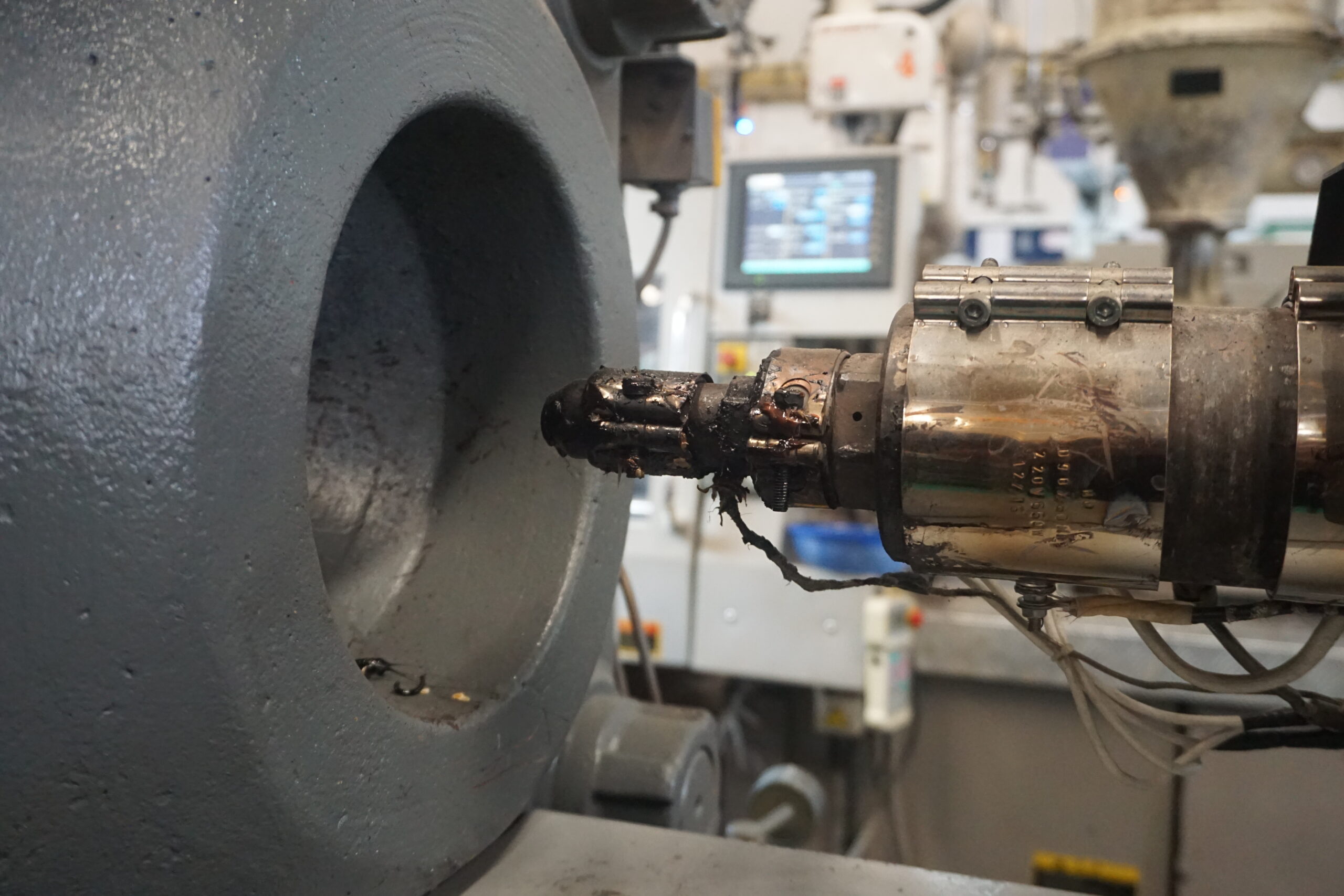

With over 20 years of experience in plastic injection and mold making. We are a leading plastic injection molding company providing total solutions from in-house mold making, mold modification and repair to plastic injection and secondary process such as silk screening, color spraying, pad printing, color dropping, UV coating, ultrasonic and hot stamping.

We also offer basic assembly process for customers if required.

We are specialized in engineering plastic components for electronic, automotive, household, cosmetics, medical device and solar energy housing component towards any other plastic items which requires quality and precision.

With more than 150 skilled staffs and our strong commitment, we deliver highest quality products and services for highest satisfactions to our valued customers.

Thailand Plastic Injection Manufacturer and Mold Maker

With more than 150 skilled staffs and our strong commitment, we deliver highest quality products and services for highest satisfactions to our valued customers.

leading in plastic injection

We are a leading plastic injection molding company providing total solutions from in-house mold making, mold modification and repair to plastic injection and secondary process such as silk screening, color spraying, pad printing, color dropping, UV coating, ultrasonic and hot stamping.

SAMPLE PARTS

With more than 20 years of our experience in mold making and injection molding, and with our strong commitment in quality and delivery, we have been trusted by many well recognized international and multi-national companies to be their “One-Stop Services” provider for plastic parts.

TRUSTED BY